B Series 15-inch Milling Machine CNC System (Horizontal)

B0x-NX5A1V-M8

Follow frequency:次

Product type:B0x-800M Series

Follow frequency:次

Product type:B0x-800M Series

Name | B01-800M Series | |

B01-NX5A1V-M8 | ||

System Specifications | Maximum Supported Channels | 8 |

Maximum Axis Count (Single Channel) | 12 | |

Maximum Linked Axis Count (Single Channel) | 6 | |

Maximum Spindle Count | 10 | |

Maximum Expandable Axis Count | 40 | |

Display Screen Size | 15-Inch Vertical | |

DA/AD | Optional | |

Operating System | RT Linux | |

Memory | 2GB | |

Program Capacity | 8GB | |

Preload Word Count | 8000b/s | |

Minimum Control Unit | 0.00001mm | |

Maximum Tool Compensation Groups | 160 Groups | |

Transmission | USB/RS485/LAN/WIFI | |

Bus Functionality | MECHATROLINK-Ⅲ/EtherCAT | |

Absolute Value Functionality | Supported: M-III, EtherCAT, MODBUS 485, SSI Absolute Encoder | |

Maximum Expandable I/O | 256-Point IO | |

Industrial Internet of Things (IIoT) | Supported | |

Program Functionality | International Standard for Machining Programs (G-code) | Supported |

Macro Programming Standard | Macro B/C | |

Background Programming | Supported | |

Conversational Intelligent Programming | Supported | |

Program USB Transfer | Supported | |

Program Auto Error Checking | Supported | |

Program Locking Feature | Limited Program Programming (Optional) | |

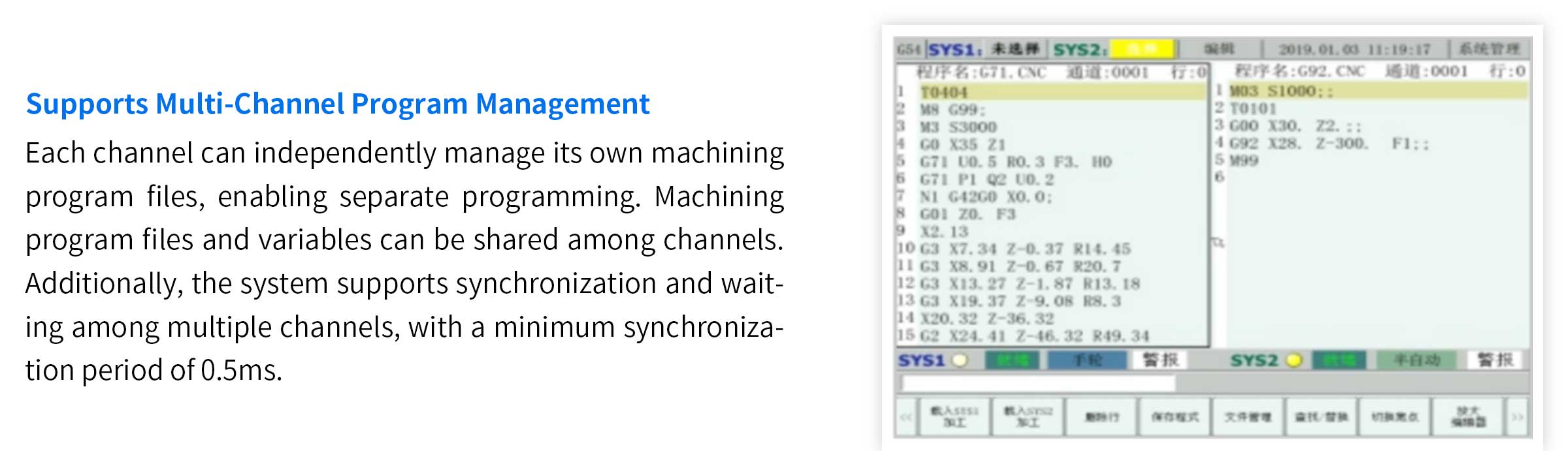

Compound Functionality | Multi-Channel Functionality | (Optional) 16 channels |

Back Spindle Functionality | Supported | |

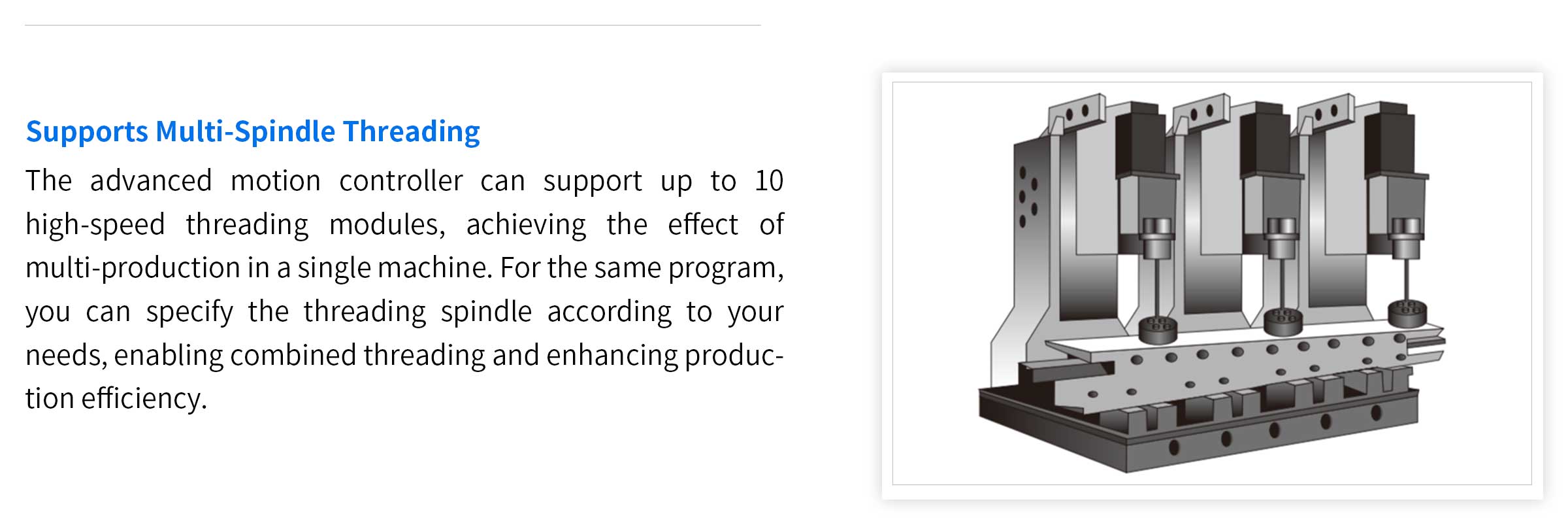

Multi-Spindle Tapping | Maximum support for simultaneous tapping with 10 spindles | |

Axis Coupling/Swapping/Blending Functionality | Supported | |

Independent Channel Control Module for Robotic Arm | (Optional) Use G-code for path planning. | |

High Speed and High Precision | Dynamic Positioning of Spindle (C) Axis | Seamless Switching and Direct Positioning Execution Without Stopping (Requires Servo Spindle) |

Continuous Motion Mode Between Program Segments | Supported | |

CONSTANT JERK Control | Supported | |

Automatic Cornering Control | Supported | |

Circular Arc Radius Speed Limitation | Supported | |

NURBS Fitting | Supported | |

Full Closed-Loop Control Functionality | Closed-loop speed control, closed-loop bus control | |

Compensation Functionality | Taper Compensation | Supported |

Backlash Compensation | Supported | |

Arc Corner Compensation | Supported | |

Bidirectional Screw Error Compensation | Supported | |

Feedforward Compensation | Supported | |

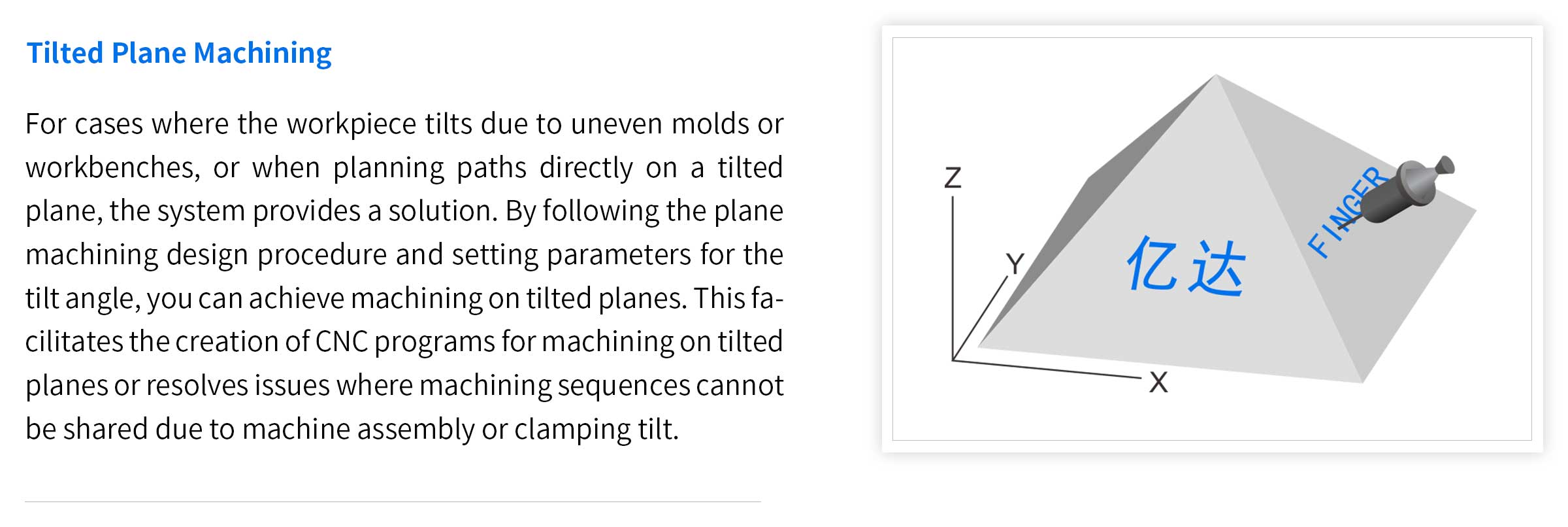

Tilted Plane | Tilted Axis Machining | Supported |

Tilted Plane Machining | Supported | |

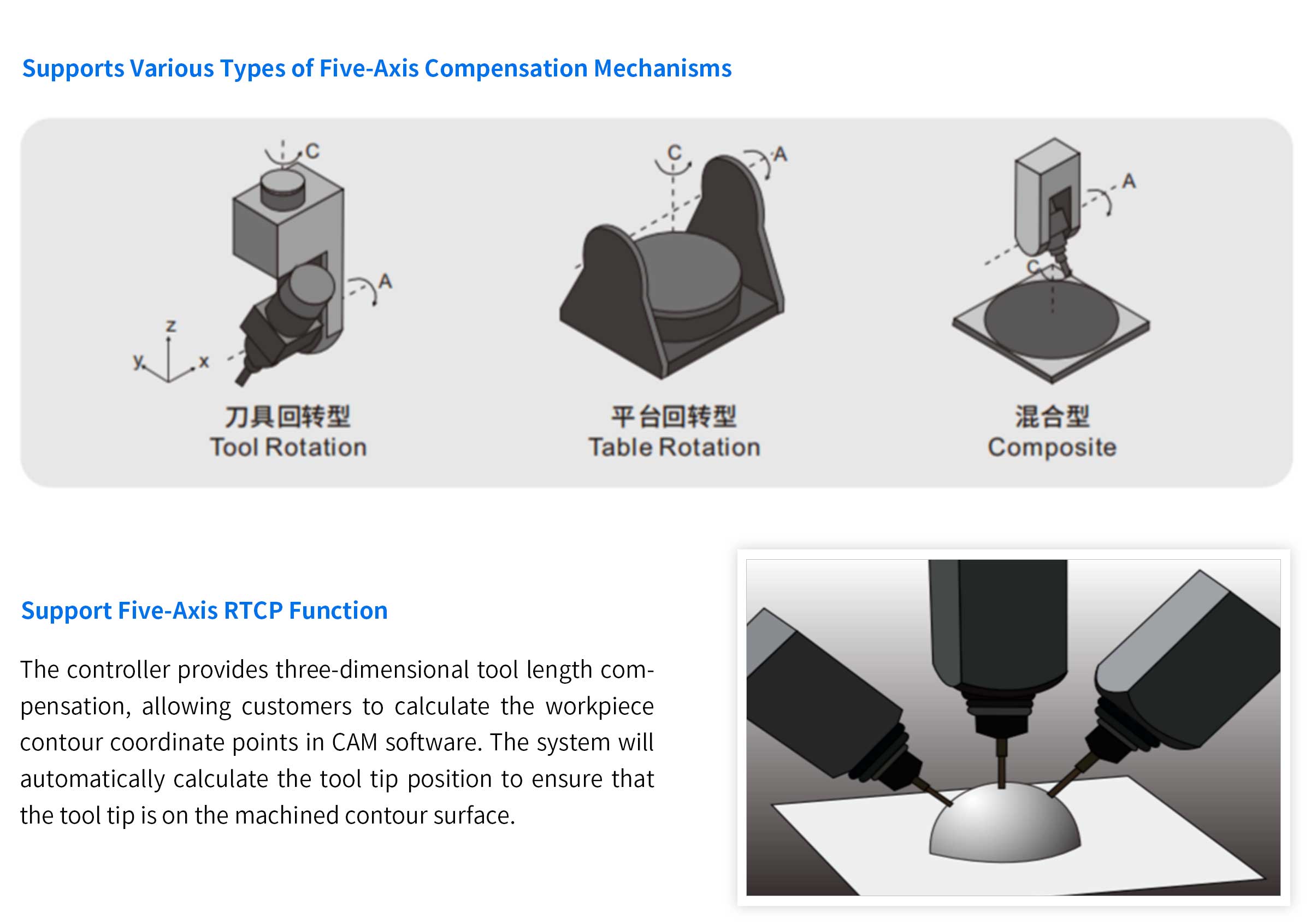

5-Axis Functionality | 5-Axis Tool Tip Point Control (RTCP) | Supported |

Smooth Tool Tip Control (Smooth TCP) | Supported | |

Auxiliary Functionality | Custom Boot Screen | Supported |

Custom M-code | Supported | |

Custom G-code | Supported | |

Bus Axis and General Axis Co-Control | Supported | |

IO Redefinition Functionality | Supported | |

DNC Machining | Supported | |

Scale Proportional | Supported | |

Acceleration and Deceleration Type | Linear Type (Supports JERK), S-Curve, Exponential | |

Tool Life Management | Time Limit, Count Limit Management | |

Protection Functionality | Safety Door, Hard Limits, Soft Limits, Unclamped Chuck Detection, Tool Changer Detection | |

Handwheel Prediction | Handwheel Prediction, Handwheel Retraction Function | |

Handwheel Interruption | Supported | |

Rapid Retraction of Tool for Tapping | Supported | |

Restart Functionality | Automatic Program Breakpoint Recovery, Customized Restart | |

Multi-Function Handwheel | Supported | |

Graphical Simulation | Graphical Preview Before Program Execution, Dynamic Plotting During Program Execution | |

Authority management | Parameter Authorization Management | |

Calendar Lock | Supported | |

Axial Load Monitoring | Supported | |

Oscilloscope Monitoring | Real-time Monitoring of System Commands and Servo Feedback Pulse Waveforms | |

Follow Error Detection | Supported | |

Spindle Speed Reach Detection | Supported | |

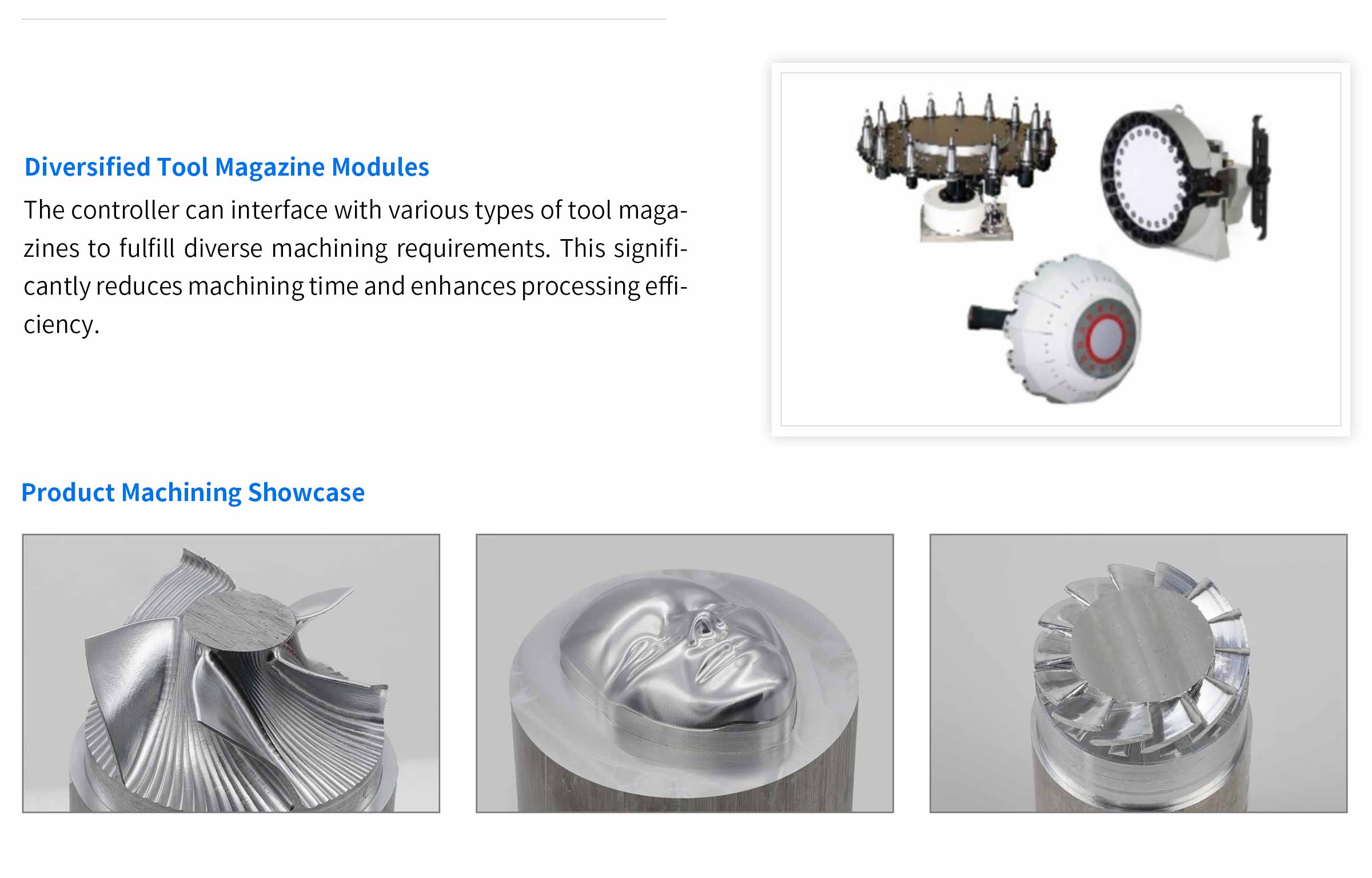

Diverse Tool Library | Disk-type Tool Library, Umbrella-type Tool Library, Customized Tool Library | |

Automatic Tool Alignment | Supported | |

Data Backup | Program Backup,Parameter Backup,Tool Compensation Backup | |

G-code Instructions | High-Precision Trajectory Control Mode | Supported |

Path Smoothing Mode | Supported | |

NURBS Curve Interpolation | Supported | |

Thread Cutting | Supported | |

Tool Offset | Supported | |

High-Speed Peck Drilling Cycle | Supported | |

Left-Hand Tapping Cycle | Supported | |

Fine Boring Cycle | Supported | |

Drilling Cycle | Supported | |

Peck Drilling Cycle with Bottom Stop | Supported | |

Peck Drilling Cycle | Supported | |

Tapping Cycle | Supported | |

Drilling Cycle | Supported | |

High-Speed Drilling Cycle | Supported | |

Semi-Automatic Fine Boring Cycle | Supported | |

Peck Boring Cycle with Bottom Stop | Supported | |

Multiple Sets of High-Speed High-Precision Parameters | Supported |