Introduction:

In the wave of intelligent manufacturing under Industry 4.0, equipment manufacturers and production factories require an information system. Finger IoT provides a complete solution for data networking collection, empowering industrial production automation. Devices can be connected to the Finger iLink digital gateway, enabling data collection and storage for a large number of devices, providing efficient, stable, and timely data.

Finger iLink is a specially designed embedded gateway for industrial sites, featuring high reliability, stability, and powerful computing capabilities.

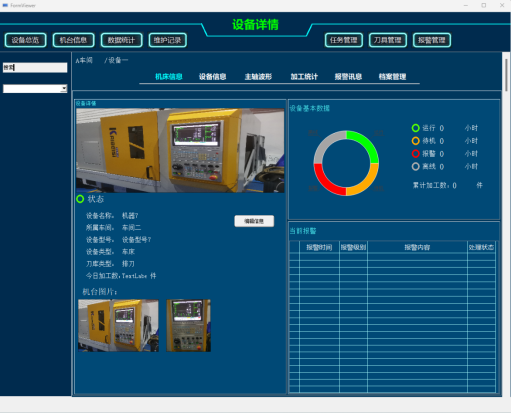

It also provides a visual HMI interface to meet various interface requirements of customers.

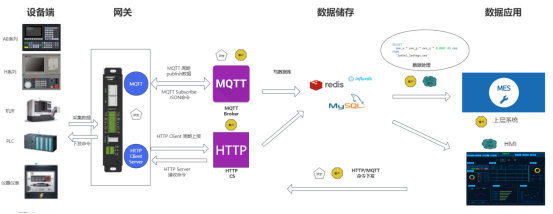

IoT Framework Diagram:

Device End

Data Collection Protocols:

Modbus Protocol: Supports standard Modbus TCP, RTU, ASCII protocols.

OPC UA

Siemens S7 series PLC

GE Ethernet RSTP Protocol

B Series Controllers

Customers only need to understand the data collection addresses of the corresponding protocols, define commands, and configure them uniformly in the software.

Advantages: Supports multiple protocol collections, with up to 20,000 data points.

Disadvantages: When the number of devices is small, hardware resources cannot be fully utilized.

Data Collection Forwarding:

Data is reported via MQTT and HTTP standard protocols.

Built-in MQTT/HTTP service can be configured to write data to default database types and tables. Customers only need to understand the field descriptions of the corresponding databases/tables.

Forwarding protocols only select periodic reporting of data, allowing customers to independently process and write data to the database.

Advantages: No need to understand device-side protocols, unified data forwarding and reporting.

Disadvantages: Limited number of forwarding protocols; additional development required for protocols not supported by customers.

Data Storage:

MQTT/HTTP Server

Uploaded data is written to the database.

Upper-level applications can send commands to the gateway, which the gateway then processes.

Provides a command interface specification. Customers define device commands themselves. They modify device data, upload files, etc., based on the interface specification.

Command list: Gateway time synchronization, gateway restart, modification of device-side variable values, file upload/download, etc.

Advantages: Abstract and unified command format, no need to individually understand device operations.

Data Application:

Upper-level systems: Display data by processing it from the database on the interface.

Application engineers can use HMI to design IoT screens, associating them with databases for data display. They need to understand database CRUD syntax.

Customers can also develop IoT interfaces themselves for data visualization, integrating with MES and other upper-level systems.

Advantages: Data is uniformly sourced from the database, facilitating data processing and display.

Application Scenarios:

CNC machine tool industry

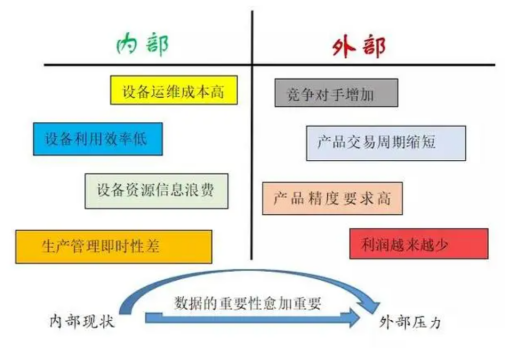

Current Issues:

Under the backdrop of Industry 4.0 and Made in China 2025, industrial manufacturing enterprises are increasingly realizing the urgent importance of extensive data acquisition and effective utilization. As CNC machine tools serve as the backbone of industrial production, their digital transformation has become imperative.

"Data" has become the most valuable "mineral resource" of this era and is an indispensable part of manufacturing enterprises' strategic planning and decision-making.

Introduction of Application Scenarios:

Data Collection: As an IoT digital gateway, Finger iLink facilitates rapid communication and connection with CNC machine tools through various communication protocols based on different CNC systems. It enables real-time data collection of all core data from CNC machines and online monitoring of equipment data.

Data Utilization: Finger iLink is capable of storing and forwarding various core data, including equipment status, operational data, fault information, production data, and energy consumption data.

It consolidates detailed data such as the status, production output, power consumption, and equipment utilization rate analysis of all CNC machine tools within the factory. This data is presented visually through HMI dashboards, enabling transparency of data and providing a strong basis for company development decisions.

Traceable Data:

Finger iLink can store and forward various core data, including equipment status, operational data, fault information, production data, and energy consumption data.

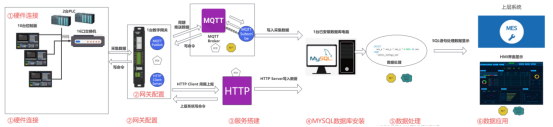

Usage Process:

Scenario Description: Currently, there is a need to collect data from 10 B-series controllers and 2 Siemens S7 400 PLCs. This data will be collected and forwarded using the digital gateway, and then written into a MYSQL database. Finally, it will be displayed in the upper-level system.

Hardware Connection:

1. All controllers and Siemens PLC are connected to the switch via Ethernet cables.

Remarks:

One port of the gateway is connected to the switch, enabling the devices and the gateway to be on the same network segment.

Hardware Inventory:

| Hardware | Quantity | Remarks |

|---|---|---|

| Controllers | 10 | |

| Siemens PLC | 2 | |

| Ethernet cables | 13 | |

| 16-port switch | 1 | |

| Digital Gateway B10 | 1 |

Hardware Equipment Diagram: [Illustration of hardware connections]

2. Gateway Configuration

Define Data Collection Requirements:

For controllers, choose the Gateway Controller Collection Driver.

For S7 400 PLC, select the Siemens S7 Series driver.

Determine the data addresses and commands required from the equipment side.

Utilize the Gateway iLink gateway software development system for configuration.

Select appropriate collection drivers:

Configure Forwarding Protocol:

Choose MQTT forwarding protocol driver.

Configure MQTT connection information, including specifying the push frequency.

Map device endpoint tables to MQTT forwarding point tables.

Configure MYSQL Database:

Specify the database IP, port, user credentials, and designate the database name for storage.

3. Service Setup

Choose MQTT/HTTP Service:

Note:

Clients can develop their programs to receive and store uploaded data.

Clients should independently plan and create database tables and storage methods.

Use the default MYSQL writing method provided by the gateway.

Configure database connection information.

Understand the database table structure and field meanings.

4.MYSQL Database Installation

Determine Database Writing Method:

Note:

Clients can develop their programs to receive and store uploaded data.

Clients should independently plan and create database tables and storage methods.

Use the default MYSQL writing method provided by the gateway.

Configure database connection information.

Understand the database table structure and field meanings.

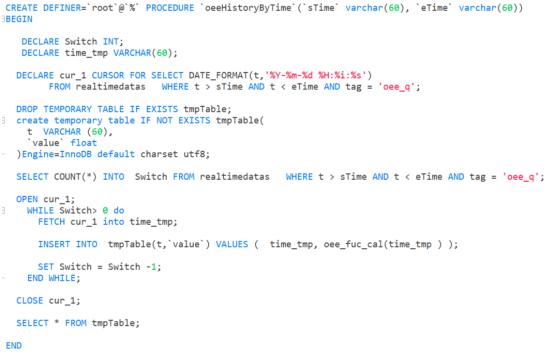

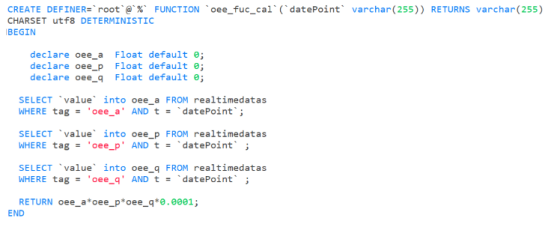

5.Data Processing

Process Raw Data in the Database:

Example: Calculate OEE (Overall Equipment Effectiveness).

Query availability rate, performance index, and quality index from historical data tables.

Perform multiplication calculations.

6.Data Application

Development Using HMI Software:

Develop interfaces using HMI software.

Drag and drop IoT plugins and link them to the database for data visualization.

Export data reports.

Client-Developed Program for Visualization Interface:

Independently develop programs for visual interfaces.