Preface

The year 2022 has been full of ups and downs, with turbulence and challenges abound. Despite the prevailing environment, Finger has remained true to its original aspirations, forging ahead, and grasping future trends, continually innovating with new products and technologies. Today, we are honored to share with you the dynamic developments, achievements, and trends of Finger's products, and witness the launch of our new products and technologies.

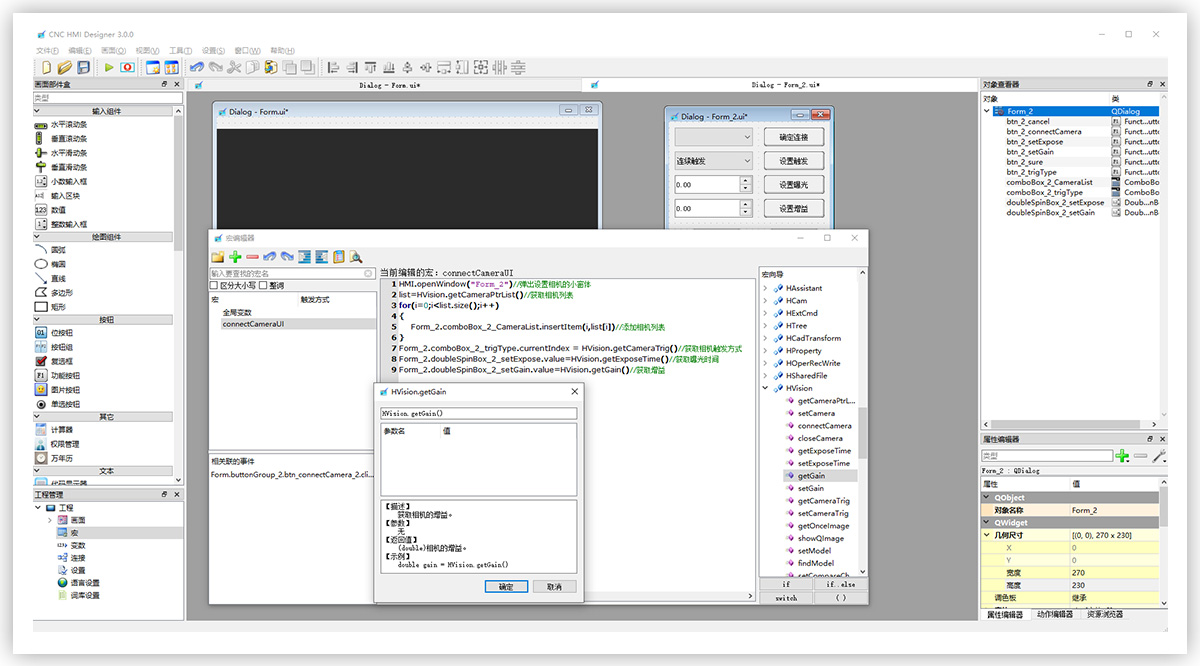

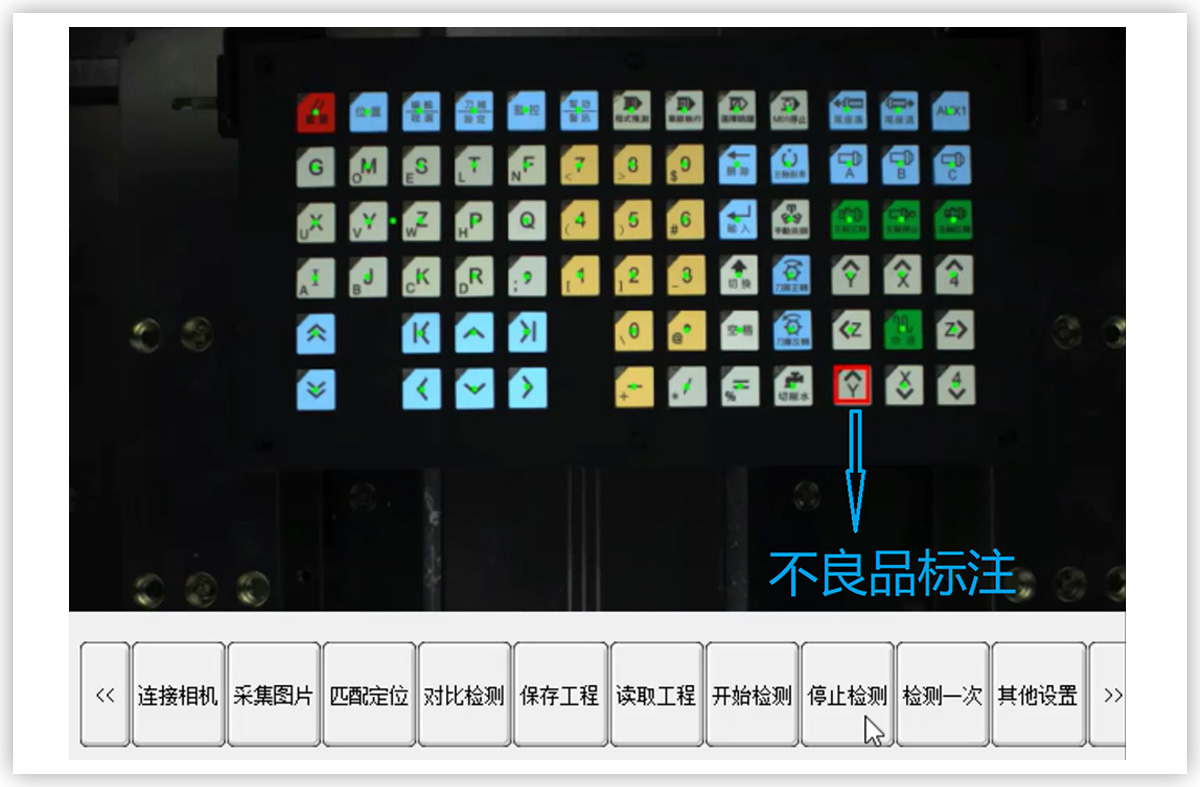

Multi-functional Vision System - Embedded Vision

Low Cost

Embedded Vision Functionality, No Need for PC Setup

High Efficiency

Direct Connection of Vision Devices to the Controller, Reducing Data Transmission, Higher Efficiency

Strong Stability

Developed with Mature Vision SDK, Functionality is Stable and Reliable

Open Design

Provides Abundant Vision Interfaces, Customizable Vision Functionality

Multiple Interface Invocation

Offers C++, Python Invocation Interfaces

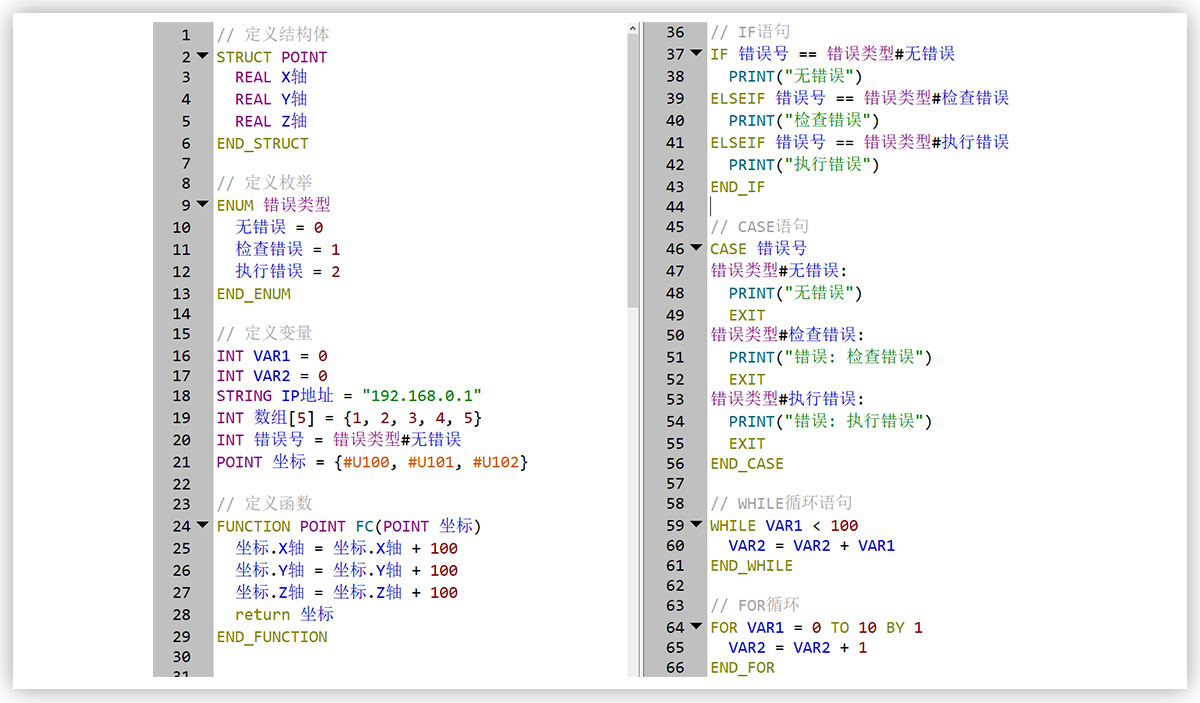

Macro Programming Language and Development Tool - Macro C

Support for Chinese Variables

Allows Definition of Local Variables, Making Programs More Intuitive and Readable

Comprehensive Programming Statements

Utilizes Conditional and Loop Statements to Implement Complex Logic

Custom Data Types

Supports Definition of Structures and Enumerations, Facilitating Data Management

Integrated Development Environment

User-Friendly Code Editor with Various Built-In Development Tools

Online Debugging

Set Breakpoints, Execute Single Steps, Making Debugging More Convenient

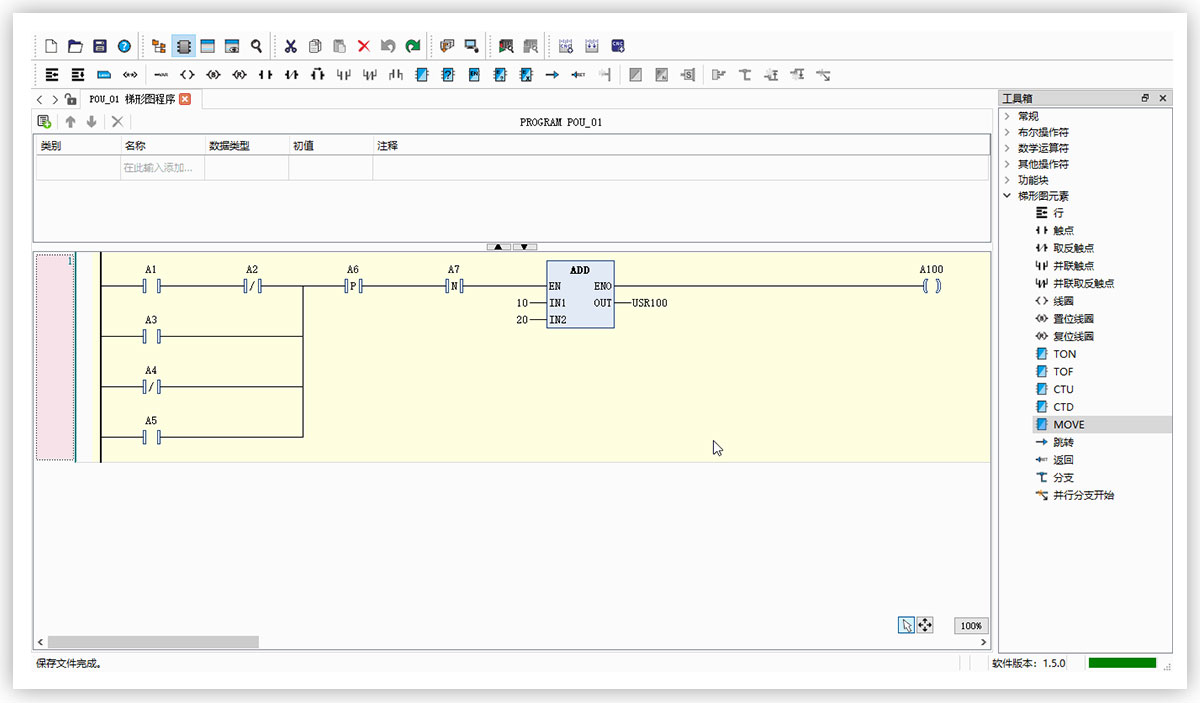

All-New Ladder Diagram Programming - PLC

Simple Operation

Automatic Component Layout, with Flexible Drag-and-Drop Functionality

Easy to Get Started

Editing Operations Reference CODESYS, Low Learning Cost

Dynamic Error Checking

Detailed Error and Warning Messages, Reducing Mistakes

Debugging and Troubleshooting

Intuitive Display of Values and Status in Monitoring Function

Refactoring Function

Bulk Modification, Automatic Refactoring, Reducing Project Maintenance Complexity

Efficient and Intuitive Programming - CAD/CAM

Powerful 2D/3D Editing Capabilities

Equipped with General CAD's 2D/3D Editing Capabilities, Easily Meeting High Graphic Editing Demands

Convenient and Intuitive Editing Operations

Preview Processed Objects and Tool Paths During Editing

Modular HMI

Used as an HMI Plugin, Easy to Develop and Ready to Use

Advanced Simulation Technology - Early Visualization and Rapid Error Correction

Quick Preview, Master the Entire Machining Process

Accurate Modeling, Grasp Process Details

The Era of Effortless Interaction - Advanced Interactive Technology

3D Display

What You See is What You Get

Touch Operation

Embrace the Era of Touchscreen Devices in Everyone's Hands

Zero-Threshold Programming

Drawing Inspiration from Top Touch Modeling Software, All Operations Align with Human Intuition

Multi-Platform Availability

Accessible on PC/CNC/Mobile Devices, with Data Exchange between Each Platform

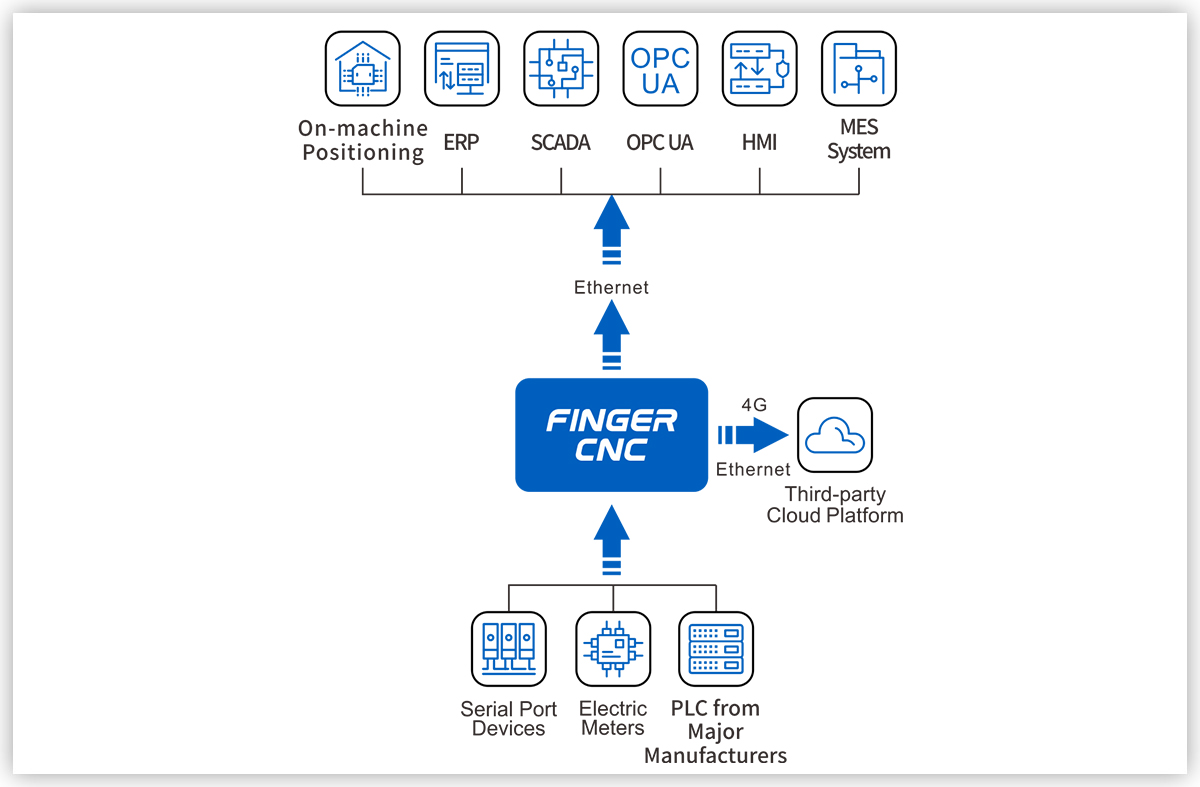

Towards Digitization - Digital Gateway

Networking Methods

Supports Ethernet connection, LAN/Serial port, and other device connections.

Automatic reconnection to ensure continuous device networking and real-time data collection.

Stable Structure, Easy Deployment

Hardware designed to withstand complex and harsh industrial environments, ensuring data stability.

Various Protocol Parsing

Embedded with a rich library of industrial protocols, supporting parsing of mainstream protocols such as Siemens PLC S7 series, Omron, standard Modbus, OPC UA, and CNC machine tools.

Standardized Data Processing

Provides data forwarding services to external platforms.

Data is standardized for easier integration with external platforms using the MQTT protocol.