Introduction

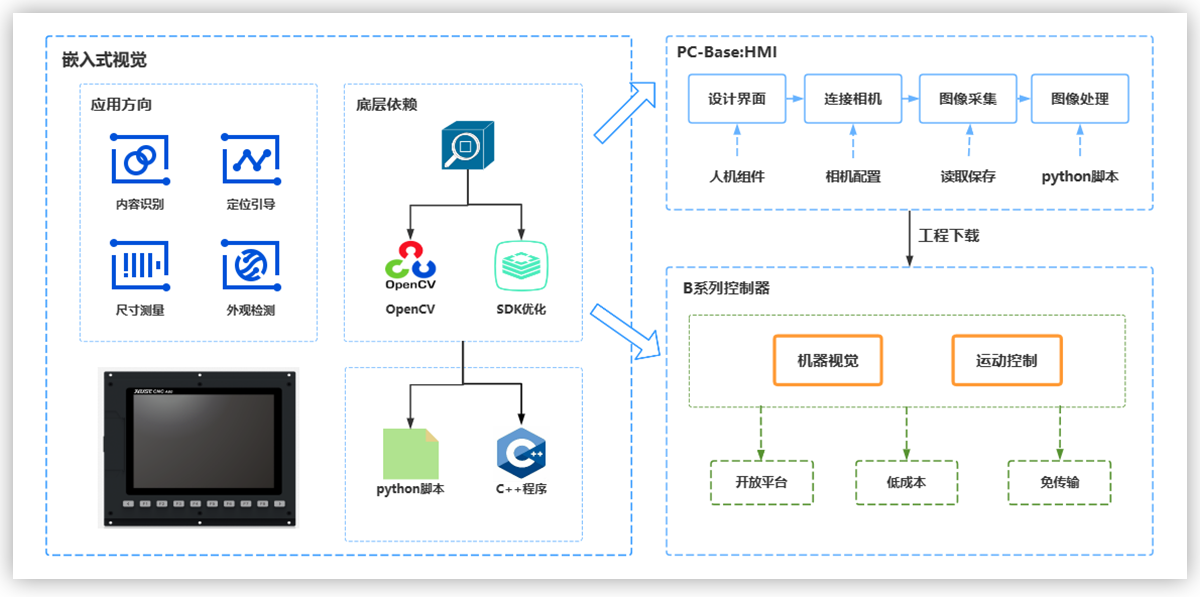

For cost-effective, mid to low computational vision applications, we adopt an integrated solution combining motion control and machine vision. This solution leverages the high computational power of the B Series controller's multicore hardware architecture and distributed software deployment technology to integrate machine vision algorithms. Machine vision computations are performed internally within the controller, facilitating internal data interaction with motion control. This improves data flow efficiency, making vision detection deployment more convenient, cost-effective, and ensuring performance.

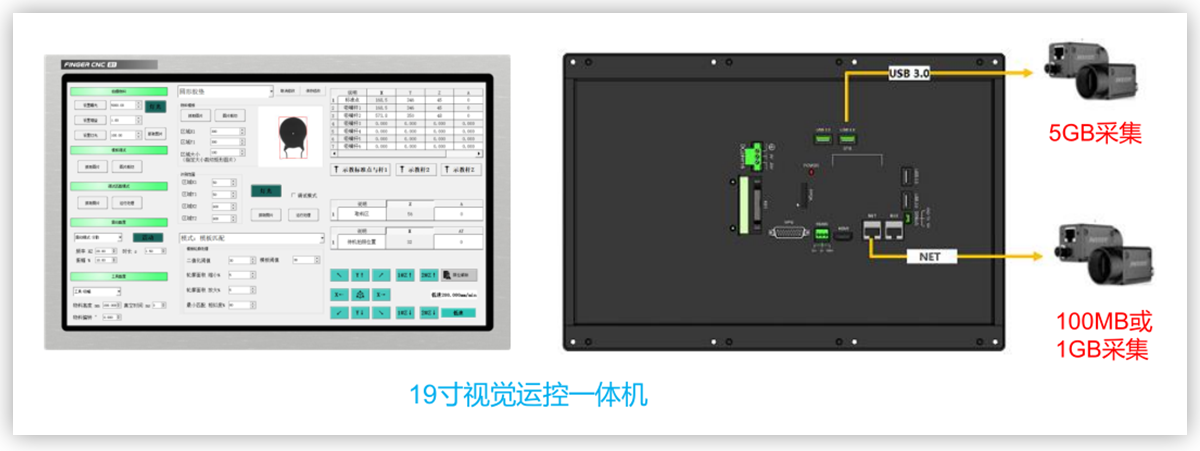

Basic Architecture of the Vision Motion Control Integrated Machine

The vision motion control integrated machine embeds the open-source OpenCV and internally developed vision processing SDK. On one hand, users can freely build vision processing programs using open-source OpenCV on the controller. They can simultaneously control directly connected cameras, process images, and perform motion control to achieve integrated vision computation and motion control solutions.

By employing the vision plus motion control integrated solution, the vision module within the controller and the motion controller module bridge data, eliminating the time required for communication and data transmission between the controller and external vision systems. This not only significantly simplifies deployment costs but also saves time in visual control communication, greatly improving overall processing efficiency. It also simplifies the separation of services for different types of products, allowing customers to experience the value brought by integrated technology.

On the other hand, to optimize vision processing performance, the next-generation vision motion control integrated controller will also integrate a high-performance vision SDK. Users can efficiently and securely perform more complex vision processing tasks.

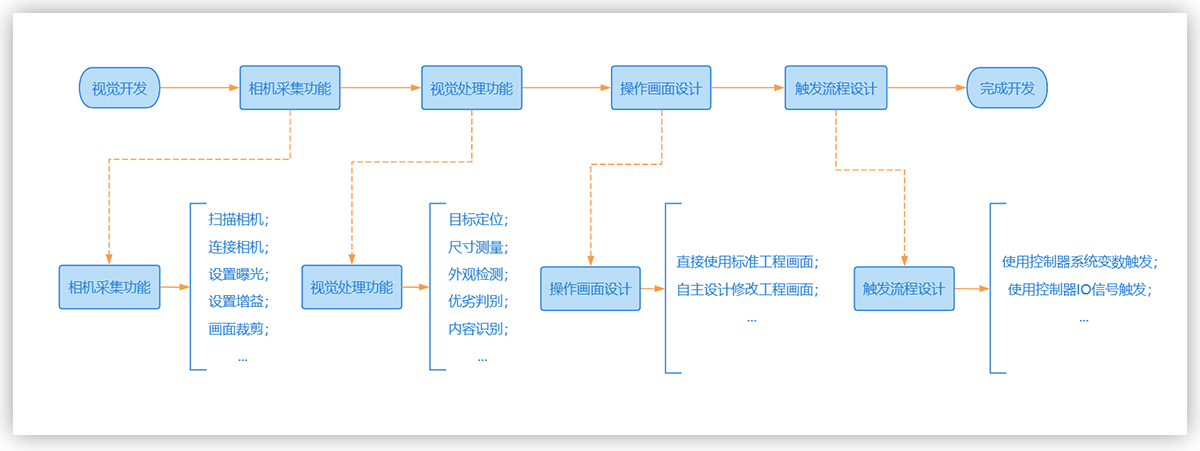

Vision Development Process

When it comes to developing new products or projects, a simple and user-friendly visual development process is key to ensuring success. Below is a typical example of a development process:

On the interface of the vision-motion control integrated machine, we can design and insert screens and functions related to vision. By using the HMI to call the user interfaces and modules related to vision, the processing flow of vision can be integrated into the motion control process. This allows customers to use the required vision functions directly on the vision-motion control integrated machine without the need to add an additional PC for vision acquisition and computation. As shown in the diagram below:

Example of HMI Calling Vision Interface

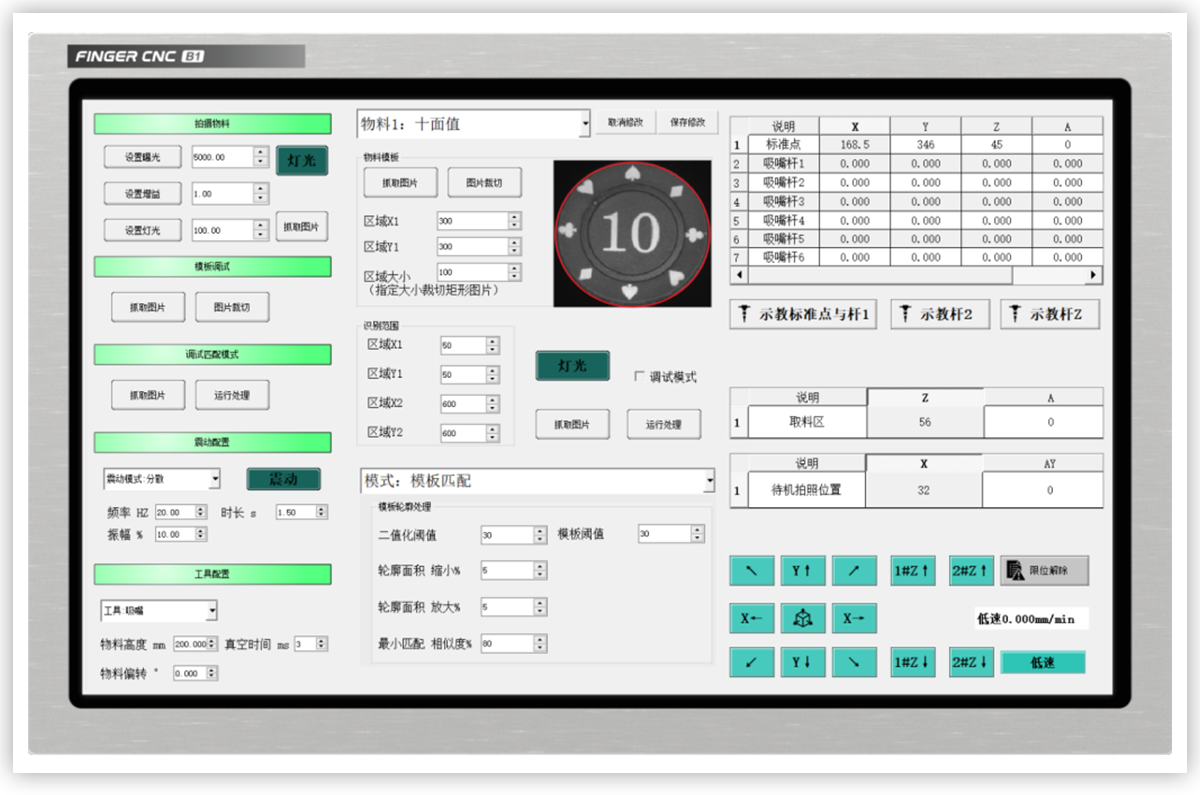

We can provide some pre-developed standard screen projects that customers can directly use for human-machine interaction operations. Customers can also customize vision-motion control screens that better suit their needs. Below is an example of a camera control screen in the standard screen project:

Standard Camera Control Screen

Case Study Introduction

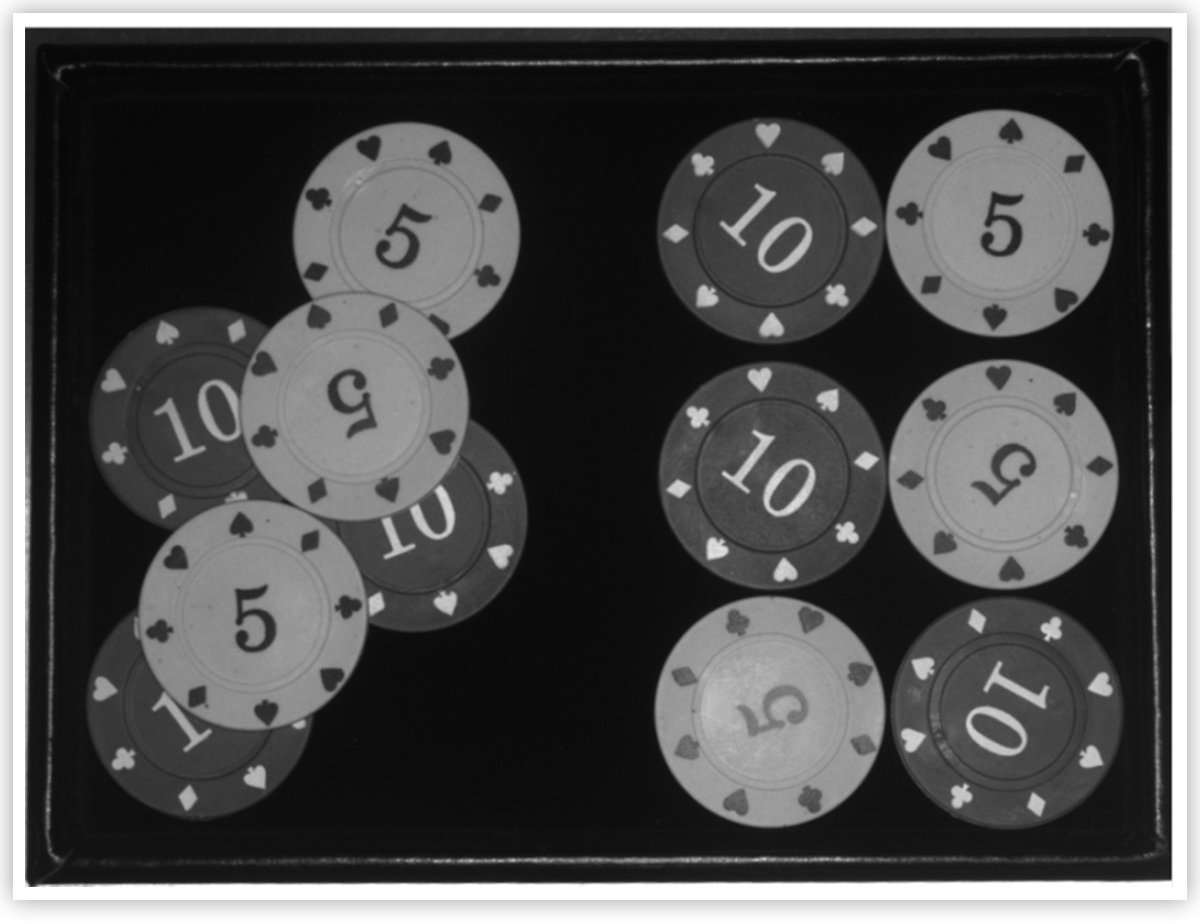

Case One:

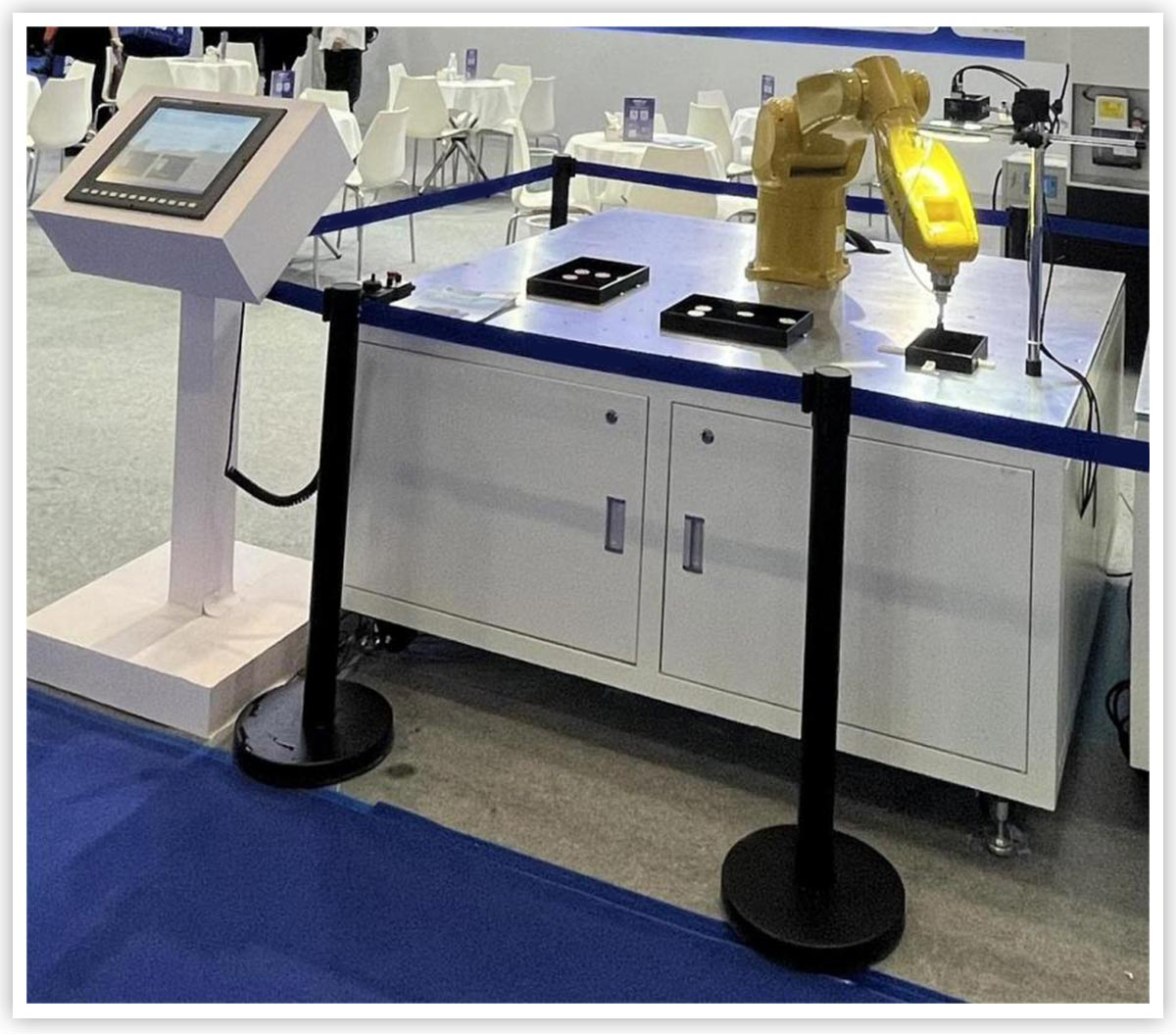

Project Name: Vision-Motion Control Integrated Automatic Sorting Machine

Project Overview: Automatically sorts materials in mixed trays with "ten-face value" and "five-face value". Identifies the type and position of materials in the mixed tray, picks them up into their respective trays, and neatly arranges them according to specified positions. It is necessary to exclude situations where materials are covered or obscured, to avoid interference with other materials during picking or picking failures.

Detection Process: Pre-set templates for two types of materials and add camera acquisition and processing trigger signals to the control flow to complete the sorting action of mixed materials. When there are no materials in the mixed tray, an alarm is triggered to pause the operation.

Image of Mixed Tray under the Camera

Controller Screen of Vision-Motion Control Integrated Automatic Sorting Machine

Physical Display of Vision-Motion Control Integrated Automatic Sorting Machine

Case Study Two:

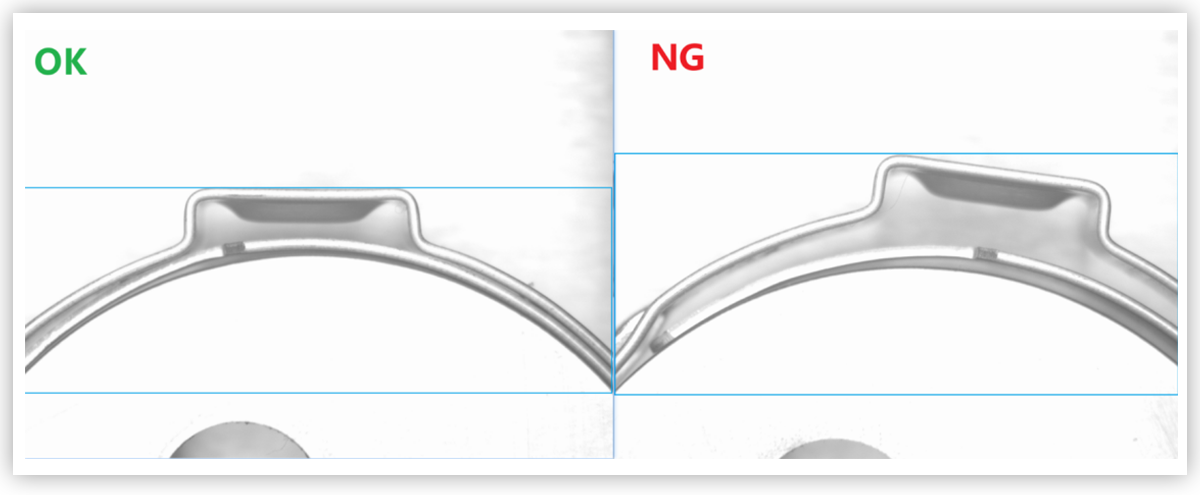

Project Name: Detection of Defective Clamps

Project Overview: The customer discovered occasional defects in clamp production, making it difficult to ensure the yield and quality of finished products. Machine vision is needed to detect and identify finished products, automatically sorting out defective products to improve the yield and quality of inspected products.

Detection Process: Capture features that distinguish between good and defective products, pre-set the feature value ranges for good and defective products, and complete the detection of defective products. The machine can also be controlled to discard defective products.

Defective Product Detection

Optical Solution Presentation

Case Three:

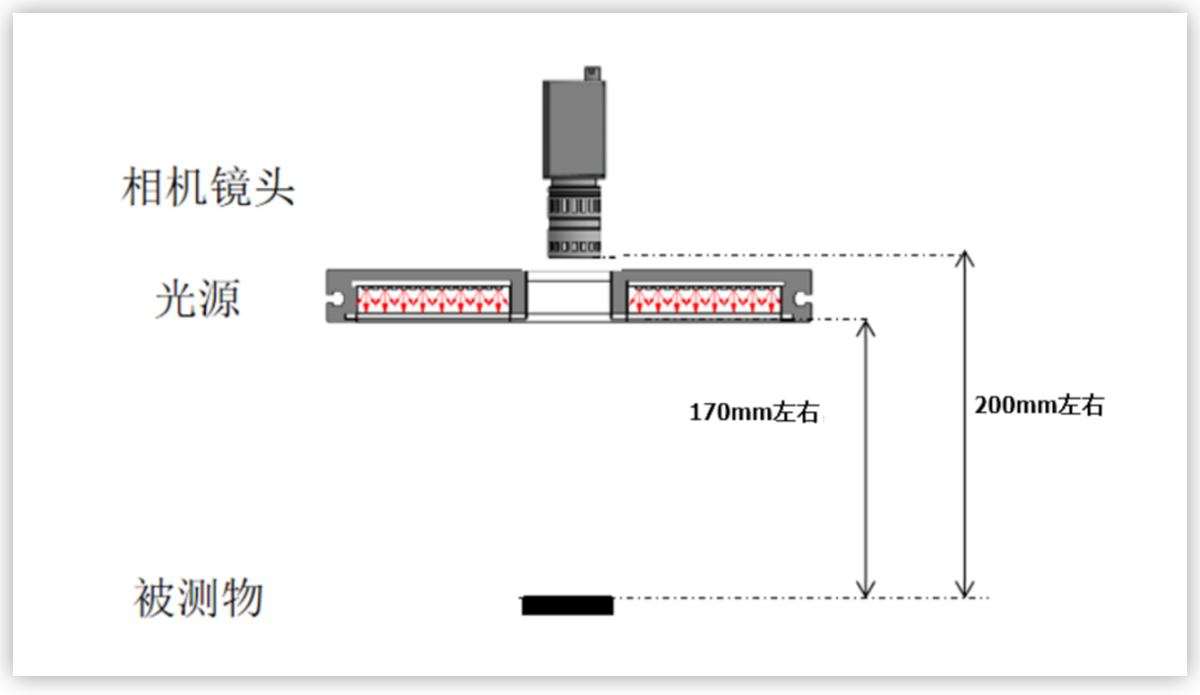

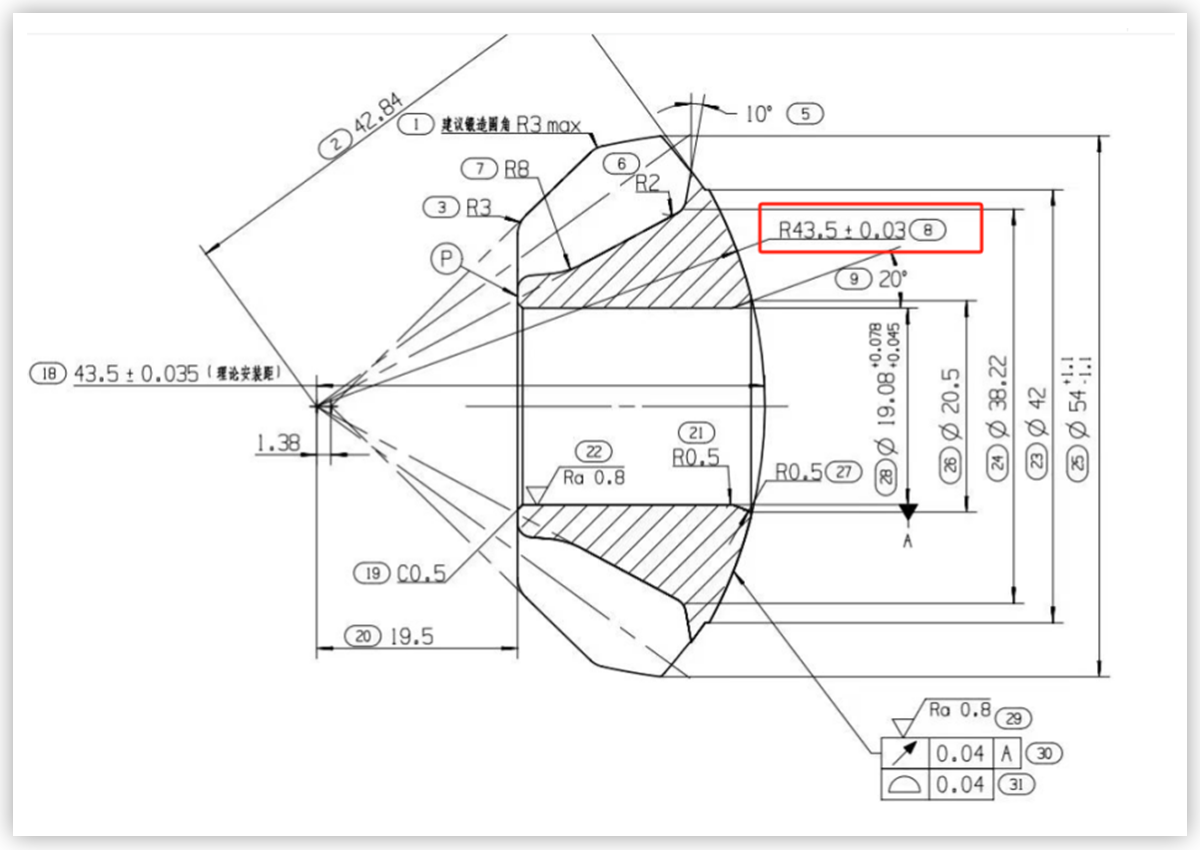

Project Name: Lathe Workpiece Dimension Measurement

Dimension Measurement Accuracy: 0.02mm

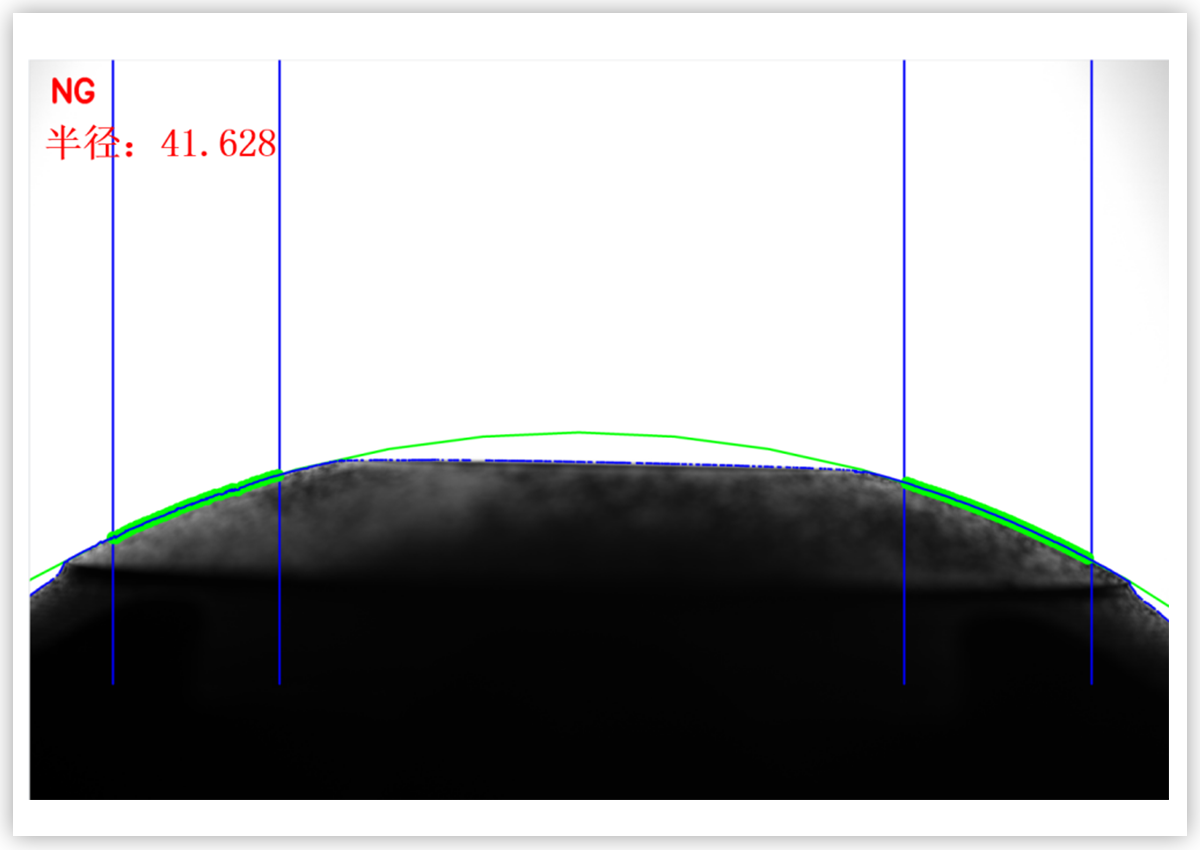

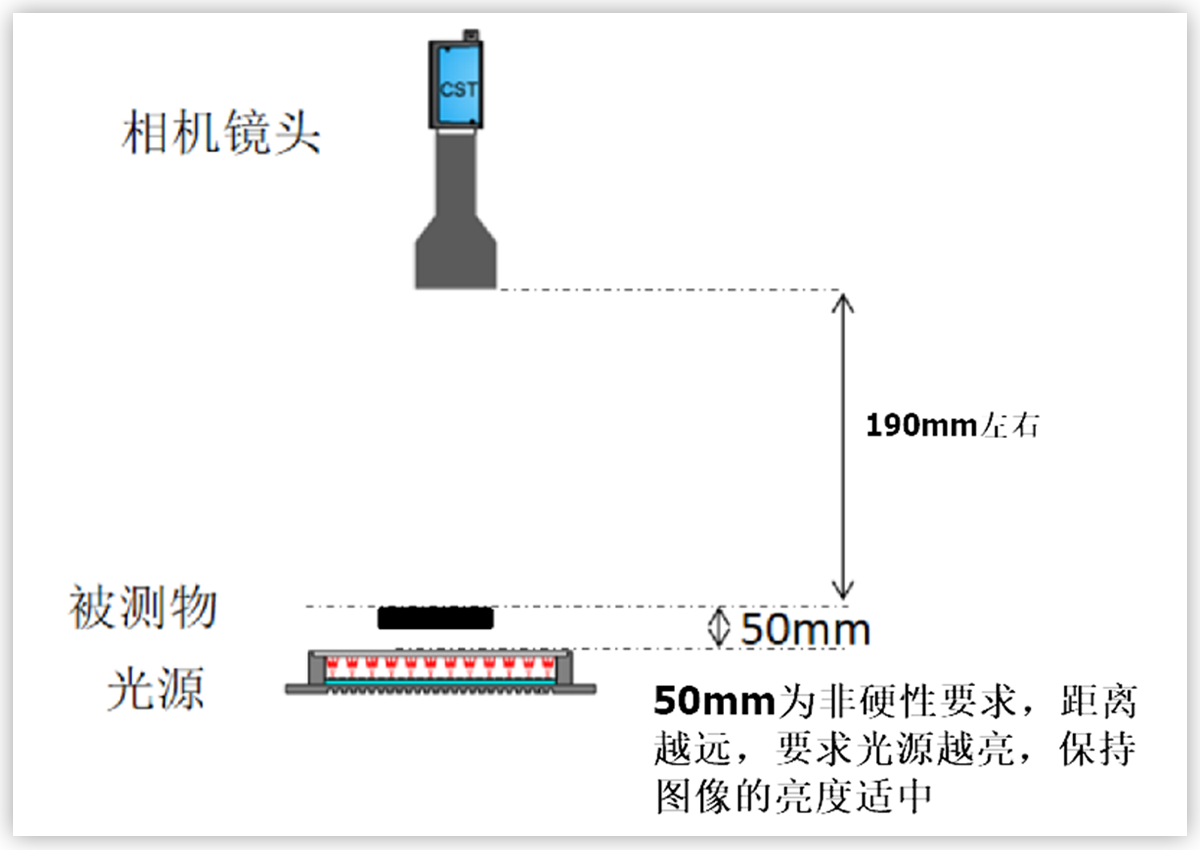

Project Overview: Workpieces from the lathe need to undergo online measurement of their dimensions after processing to determine whether they meet manufacturing tolerances. Defective products are sorted out for automatic tool compensation, tool failure warning, or tool life management. The project measures the radius of the workpiece's side curvature, and using vision for non-contact measurement is faster and more accurate. Additionally, dimensional measurement data can be used to adjust machining parameters for tool compensation, further improving the quality of production.

Measurement Process: Connect the camera to the controller, illuminate and photograph the side of the workpiece. The controller has a built-in circular arc detection algorithm. Simply set the detection range and parameters before detection to calculate the radius of the side arc of the workpiece, and then transmit the result to the machining program.

Lathe Workpiece CAD Drawing

Effect Diagram of Lathe Workpiece Dimension Measurement

Backlight Projection Optical Solution Presentation

Case Four:

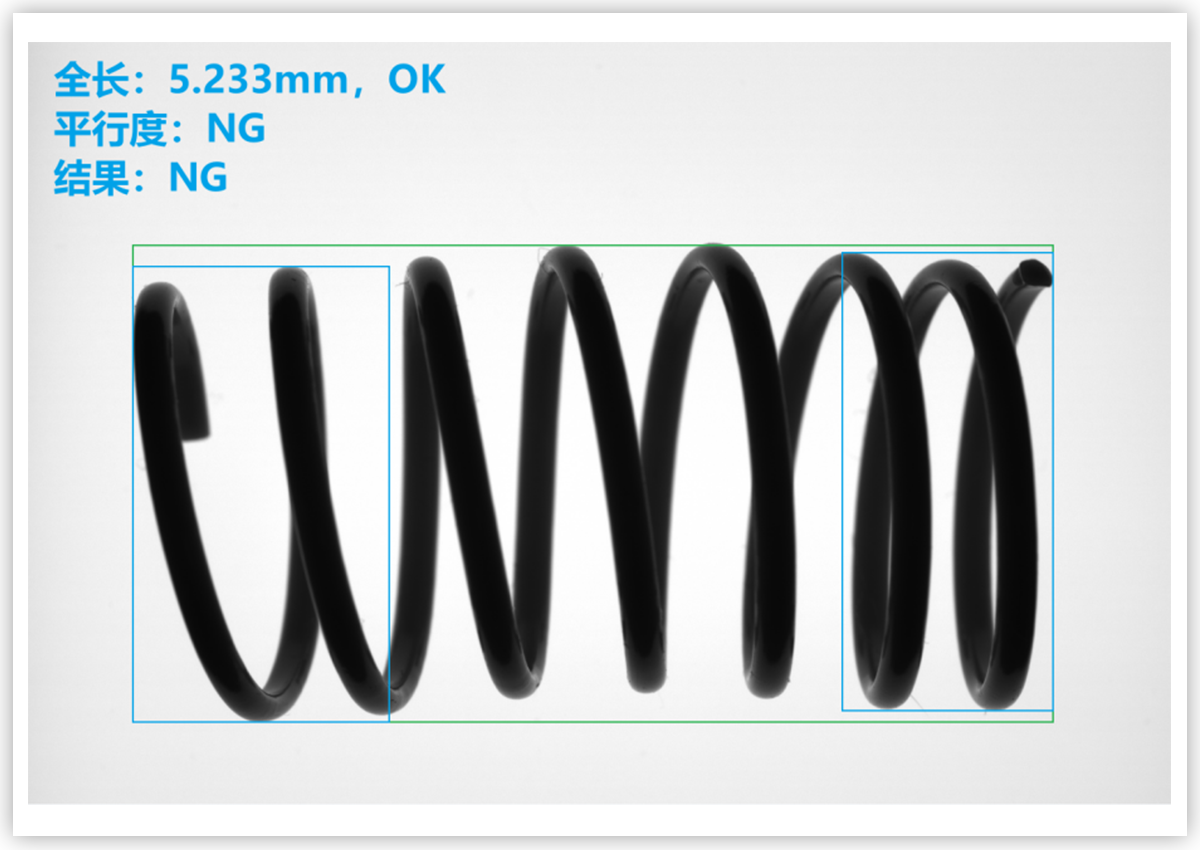

Project Name: Spring Dimension Measurement

Dimension Measurement Accuracy: 0.02mm

Project Overview: Measure the overall length of the spring, the parallelism of the front and rear ends, and the outer diameter. In the manufacturing process of springs, occasional problems such as insufficient spring length and uneven size at both ends may occur. Conventional contact measurement methods cannot be used for spring measurement. Machine vision technology is used to measure springs and provide feedback to adjust the manufacturing process.

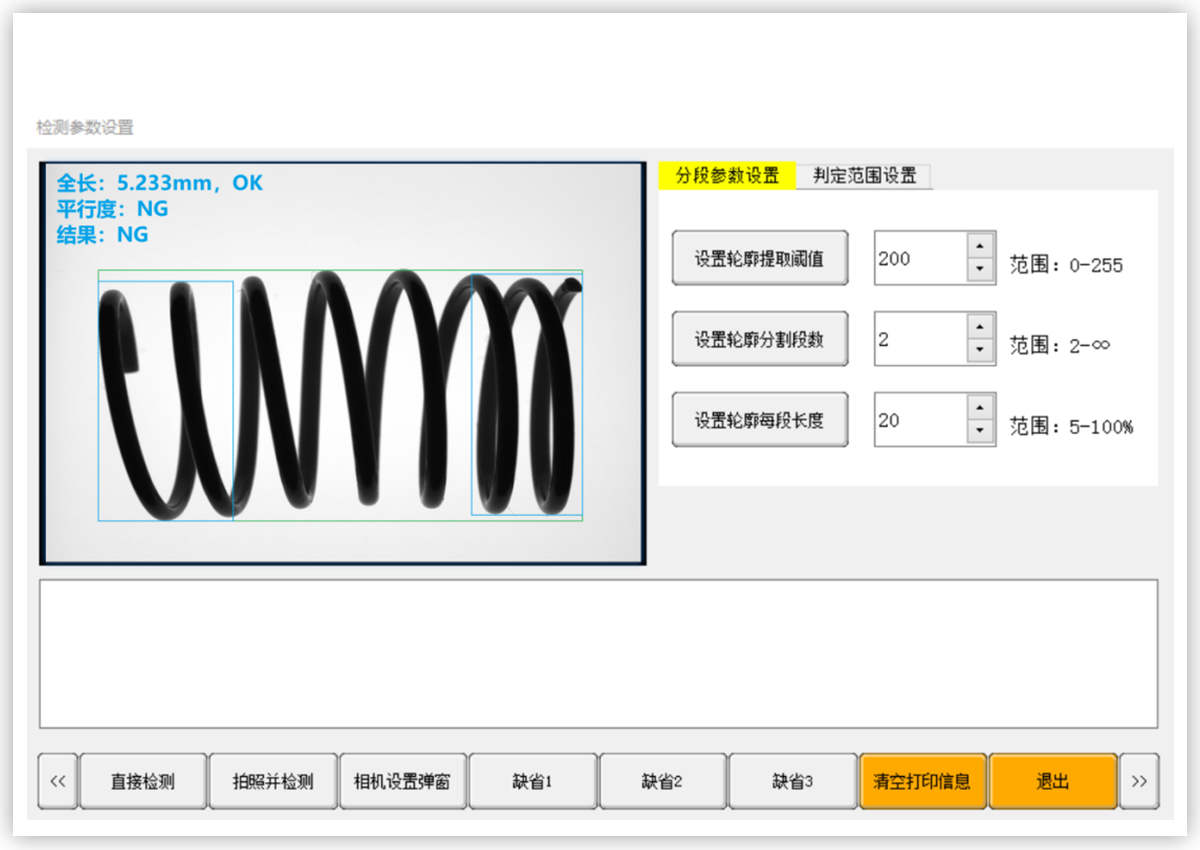

Measurement Process: The parallelism of the spring is achieved through segmented detection. Users can pre-set the number of segments and the length of each segment for segmented detection of the spring. Then, the parallelism of the spring is calculated using vision. The overall length of the spring is automatically identified and calculated by vision. If the overall length, parallelism, or outer diameter of the spring exceeds the user-set range, program compensation is automatically performed on the next product.

Spring Inspection Effect Diagram

Spring Inspection Vision Parameter Setting Screen

Advantages of Vision-Motion Control Integrated Machine

The new multi-core, high-computing power distributed architecture of the vision-motion control integrated controller has significant product advantages in developing vision projects with low to medium computing power requirements:

Efficiency: Our product can monitor real-time information such as the position, appearance, and status of objects in the production process, and perform vision processing and control directly by the controller, eliminating the need for transmission steps. This allows for online improvement of product quality and efficiency.

Cost-effectiveness: Our product adopts an embedded vision solution, eliminating the need for a traditional PC that is typically required for vision applications. Vision processing is directly performed on the controller, saving users additional equipment costs.

Ease of operation: Our product integrates familiar OpenCV and is also developing superior vision processing SDKs and specific modules. This makes it increasingly simple for customers to use and develop their own applications.