B Series 8-inch Milling Machine CNC System (Vertical)

B0x-NX2A1V-M4

Follow frequency:次

Product type:B0x-400M Series

Follow frequency:次

Product type:B0x-400M Series

Name | B01-400M Series | ||

B01-NX1A1H-M4 | B01-NX2A1V-M4 | ||

System Specifications | Maximum Supported Channels | 1 | |

Maximum Axis Count (Single Channel) | 6 | ||

Maximum Linked Axis Count (Single Channel) | 3 | ||

Maximum Spindle Count | 1 | ||

Maximum Expandable Axis Count | 6 | ||

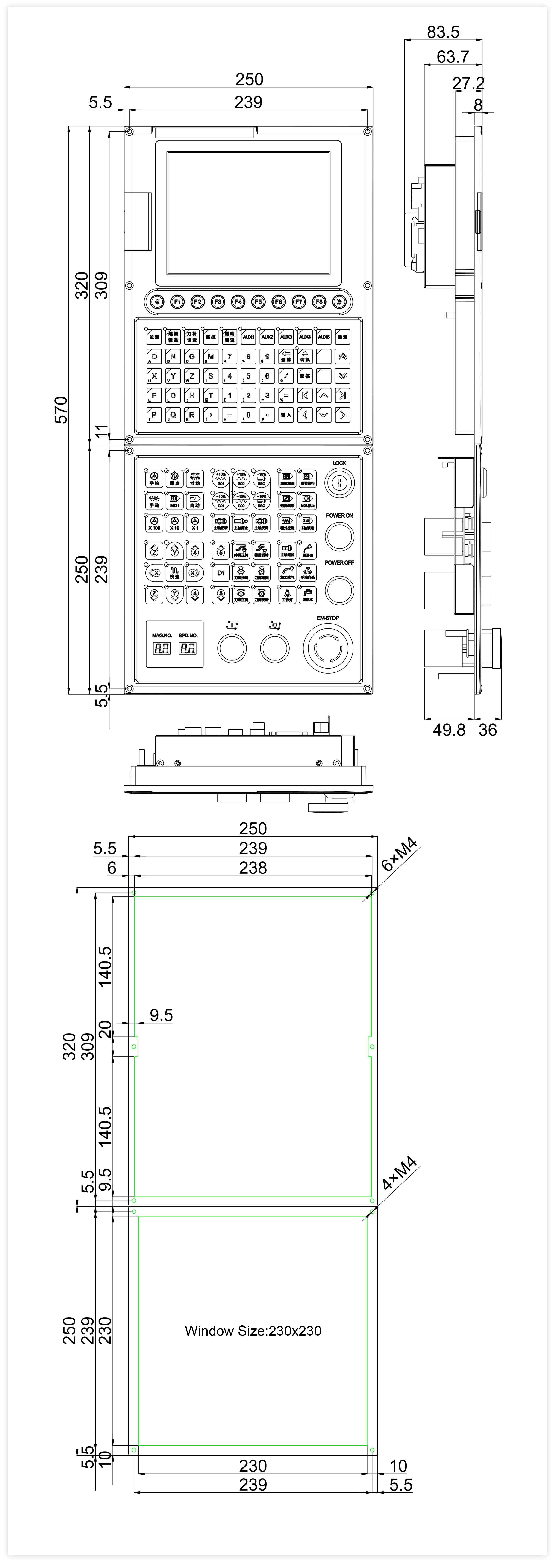

Display Screen Size | 7-Inch Horizontal | 8-Inch Vertical | |

DA/AD | Optional | ||

Operating System | RT Linux | ||

Memory | 2GB | ||

Program Capacity | 8GB | ||

Preload Word Count | 1000b/s | ||

Minimum Control Unit | 0.00001mm | ||

Maximum Tool Compensation Groups | 160 Groups | ||

Transmission | USB/RS485/LAN/WIFI | ||

Bus Functionality | EtherCAT | ||

Absolute Value Functionality | EtherCAT | ||

Maximum Expandable I/O | 64-Point IO | ||

Industrial Internet of Things (IIoT) | Not Supported | ||

Program Functionality | International Standard for Machining Programs (G-code) | Supported | |

Macro Programming Standard | Macro B/C | ||

Background Programming | Supported | ||

Conversational Intelligent Programming | Supported | ||

Program USB Transfer | Supported | ||

Program Auto Error Checking | Supported | ||

Program Locking Feature | Limited Program Programming (Optional) | ||

Compound Functionality | Multi-Channel Functionality | Not Supported | |

Back Spindle Functionality | Supported | ||

Multi-Spindle Tapping | Not Supported | ||

Axis Coupling/Swapping/Blending Functionality | Not Supported | ||

Independent Channel Control Module for Robotic Arm | Not Supported | ||

High Speed and High Precision | Dynamic Positioning of Spindle (C) Axis | Seamless Switching and Direct Positioning Execution Without Stopping (Requires Servo Spindle) | |

Continuous Motion Mode Between Program Segments | Supported | ||

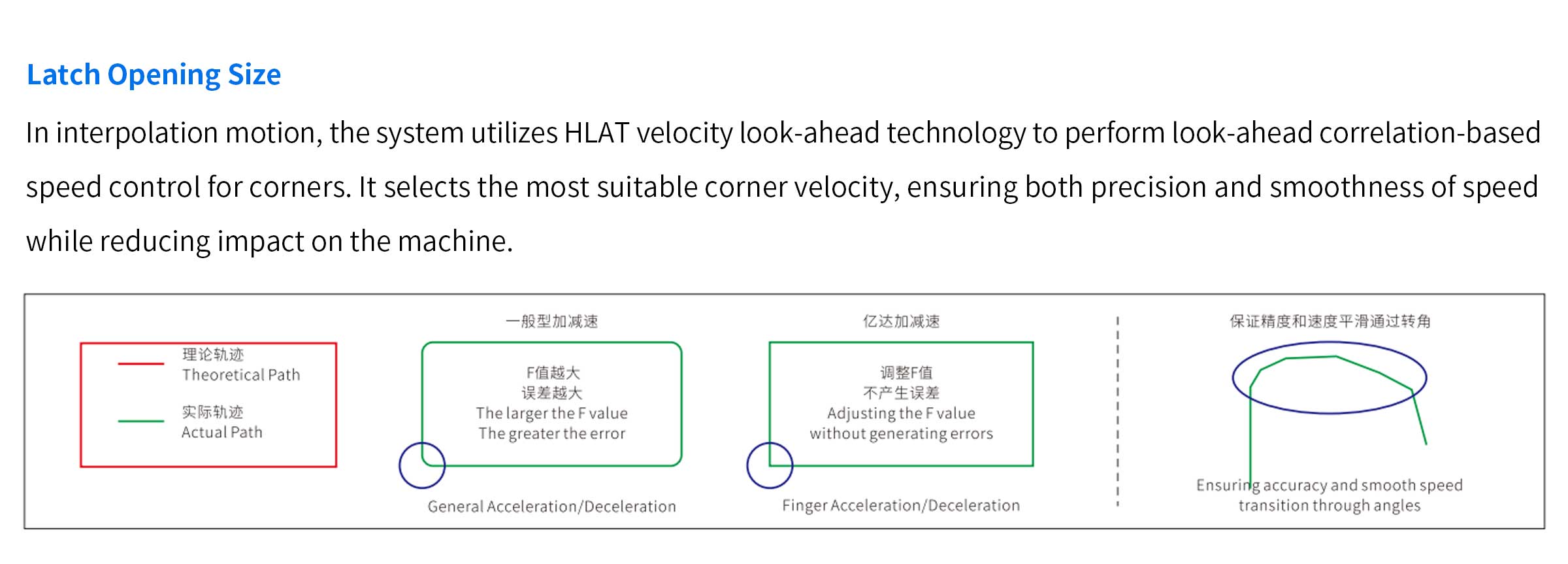

CONSTANT JERK Control | Supported | ||

Automatic Cornering Control | Supported | ||

Circular Arc Radius Speed Limitation | Supported | ||

NURBS Fitting | Supported | ||

Full Closed-Loop Control Functionality | Not Supported | ||

Compensation Functionality | Taper Compensation | Supported | |

Backlash Compensation | Supported | ||

Arc Corner Compensation | Supported | ||

Bidirectional Screw Error Compensation | Supported | ||

Feedforward Compensation | Supported | ||

Tilted Plane | Tilted Axis Machining | Supported | |

Tilted Plane Machining | Supported | ||

5-Axis Functionality | 5-Axis Tool Tip Point Control (RTCP) | Not Supported | |

Smooth Tool Tip Control (Smooth TCP) | Supported | ||

Auxiliary Functionality | Custom Boot Screen | Supported | |

Custom M-code | Supported | ||

Custom G-code | Supported | ||

Bus Axis and General Axis Co-Control | Not Supported | ||

IO Redefinition Functionality | Supported | ||

DNC Machining | Supported | ||

Scale Proportional | Supported | ||

Acceleration and Deceleration Type | Linear Type (Supports JERK), S-Curve, Exponential | ||

Tool Life Management | Time Limit, Count Limit Management | ||

Protection Functionality | Safety Door, Hard Limits, Soft Limits, Unclamped Chuck Detection, Tool Changer Detection | ||

Handwheel Prediction | Handwheel Prediction, Handwheel Retraction Function | ||

Handwheel Interruption | Supported | ||

Rapid Retraction of Tool for Tapping | Supported | ||

Restart Functionality | Automatic Program Breakpoint Recovery, Customized Restart | ||

Multi-Function Handwheel | Supported | ||

Graphical Simulation | Graphical Preview Before Program Execution, Dynamic Plotting During Program Execution | ||

Authority management | Parameter Authorization Management | ||

Calendar Lock | Supported | ||

Axial Load Monitoring | Supported | ||

Oscilloscope Monitoring | Real-time Monitoring of System Commands and Servo Feedback Pulse Waveforms | ||

Follow Error Detection | Supported | ||

Spindle Speed Reach Detection | Supported | ||

Diverse Tool Library | Disk-type Tool Library, Umbrella-type Tool Library, Customized Tool Library | ||

Automatic Tool Alignment | Supported | ||

Data Backup | Program Backup,Parameter Backup,Tool Compensation Backup | ||

G-code Instructions | High-Precision Trajectory Control Mode | Supported | |

Path Smoothing Mode | Supported | ||

NURBS Curve Interpolation | Supported | ||

Thread Cutting | Supported | ||

Tool Offset | Supported | ||

High-Speed Peck Drilling Cycle | Supported | ||

Left-Hand Tapping Cycle | Supported | ||

Fine Boring Cycle | Supported | ||

Drilling Cycle | Supported | ||

Peck Drilling Cycle with Bottom Stop | Supported | ||

Peck Drilling Cycle | Supported | ||

Tapping Cycle | Supported | ||

Drilling Cycle | Supported | ||

High-Speed Drilling Cycle | Supported | ||

Semi-Automatic Fine Boring Cycle | Supported | ||

Peck Boring Cycle with Bottom Stop | Supported | ||

Multiple Sets of High-Speed High-Precision Parameters | Not Supported | ||